MergeOne and MORE

MergeOne And More

Multi-material 2-photon polymerization (MergeOne and more)

Immerse yourself in the world of functional 3D micro-printing. Create multi-material 3D microprints with 2PP 3D printing like never before with HETEROMERGE® products.

MergeOne

Our add-on printhead system is your entry ticket to efficient 2PP multi-material printing.

MergeCam

Our process monitoring camera is for your tool-safe operations, advanced vision, and pre-alignment.

MX materials

Our optimized materials are for realizing your desired functional structures with MergeOne.

Printing services

We evaluate your multi-material ideas and offer premium printing services.

MERGEONE - the 2-photon polymerization System Add-on

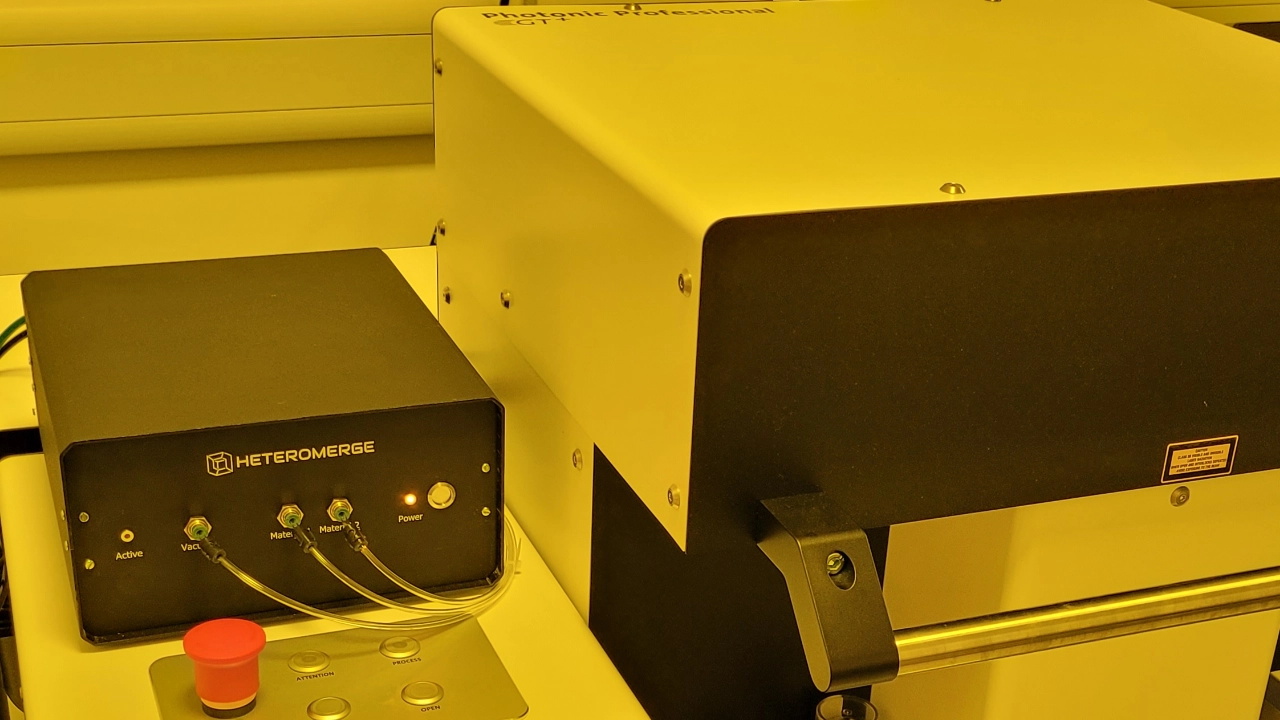

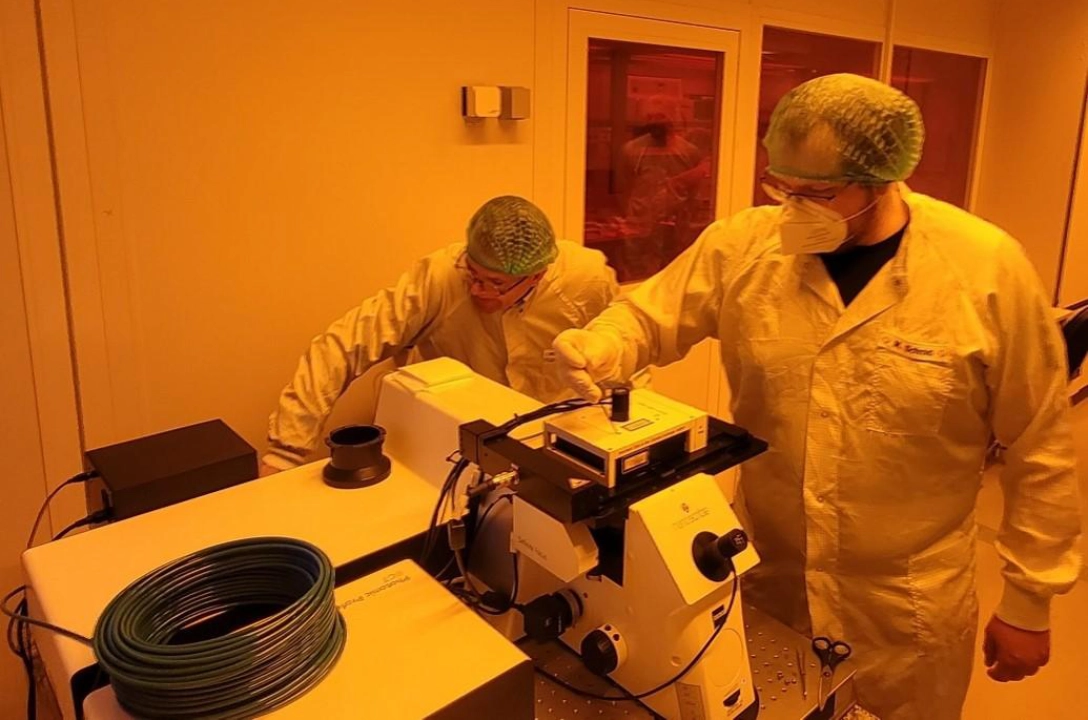

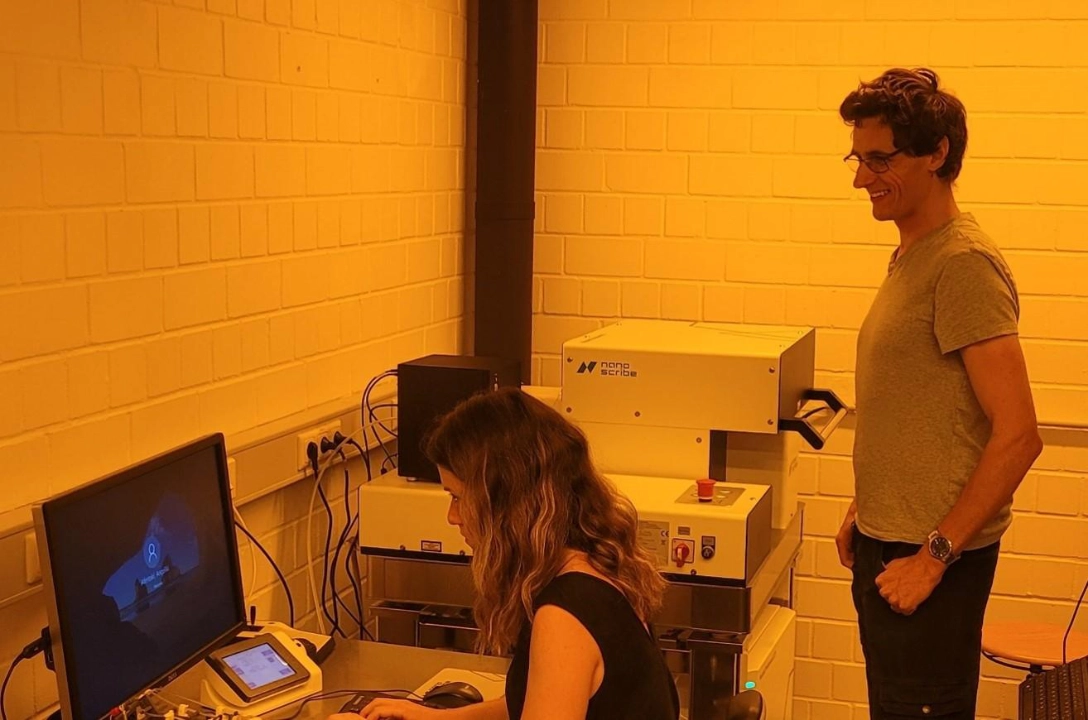

MergeOne is based on our fluidic delivery technology and does not affect the performance of your 2PP system. The MergeOne system consists of several operational components that smoothly integrate into existing 2PP systems to enable multi-material 2PP printing.

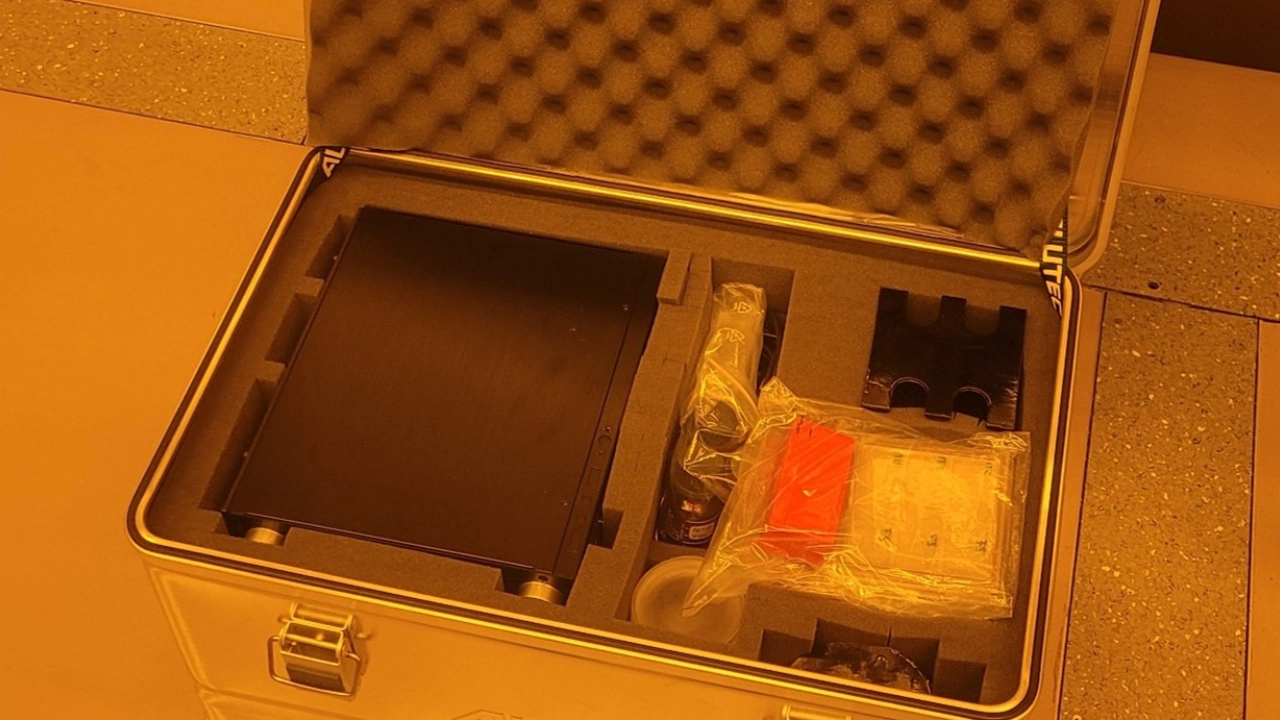

In addition, the system is delivered with sophisticated control software and supporting components for improved ease of use, seamless integration, and the safety of the upgraded 2PP printer. All components are delivered in a durable aluminum casing and installed by our engineers. Additionally, you will receive intensive user training.

MergeOne components

- Printhead

- SCULPTOR control software

- Hardware control electronics

- Wide-angle process camera

- System feedthrough and fluidic handling

- Material reservoirs and controls

- Safety features

System specifications

- Open system (commercial, custom materials)

- Up to 3+1 materials (changing + 1 initial)

- Viscosity between 0.5 Pas and 35 Pas

- For ZEISS 63x, 25x, 10x objectives

- Up to 8 bar (CDA, N2)

- Down to -900 mbar (pumps on request)

MergeOne is currently available for the following systems of Nanoscribe

- Photonic Professional GT

- Photonic Professional GT+

- Photonic Professional GT2

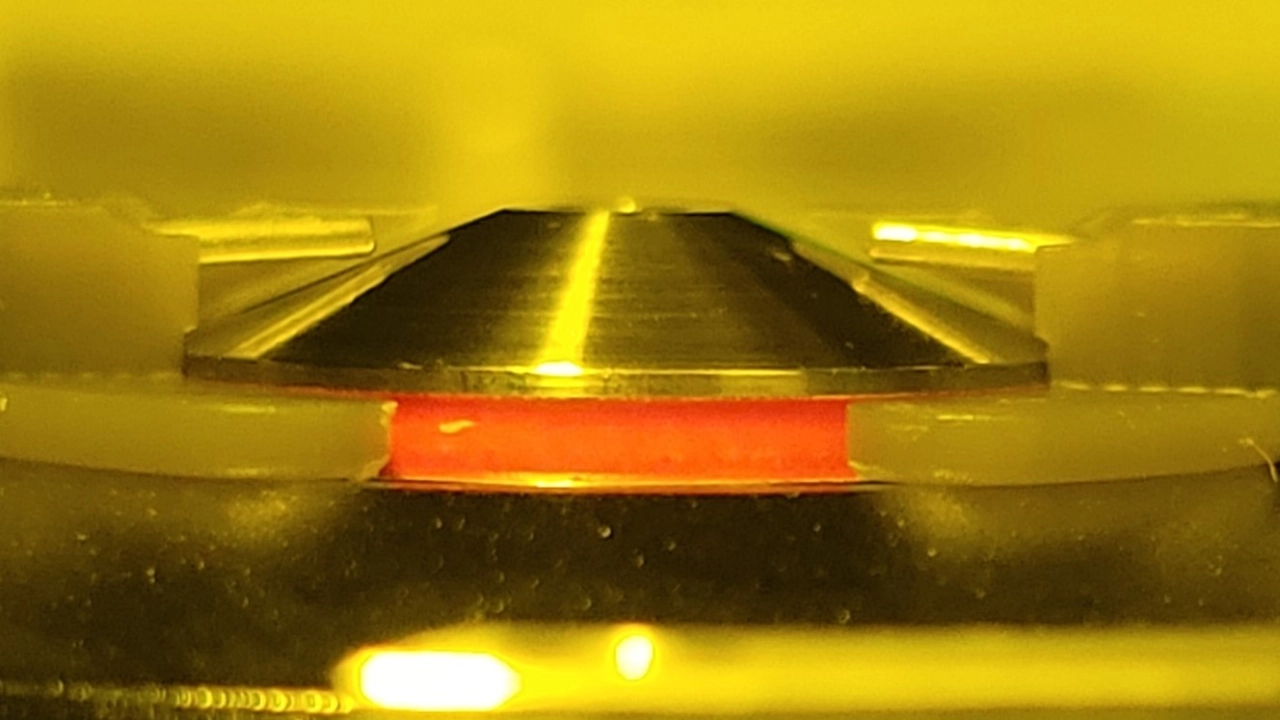

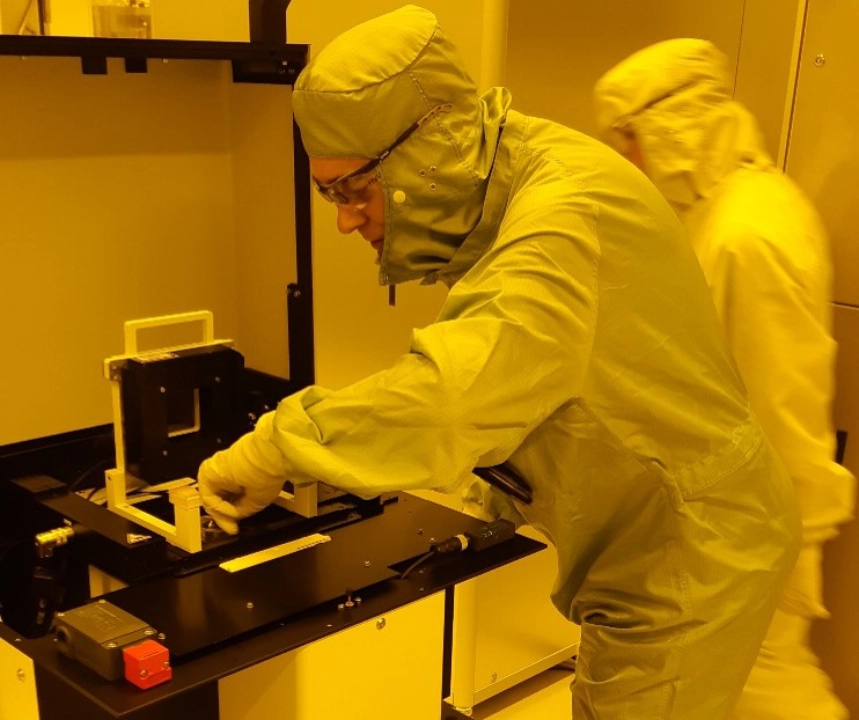

Printhead

The printhead is connected to the resin reservoir, controlled via the system feedthrough, and realizes the open fluidic exchange inside the 2PP printer. It is mounted to the focusing objective with a quick release mechanism for different objectives for user convenience. It can be easily removed for normal 2PP operation.

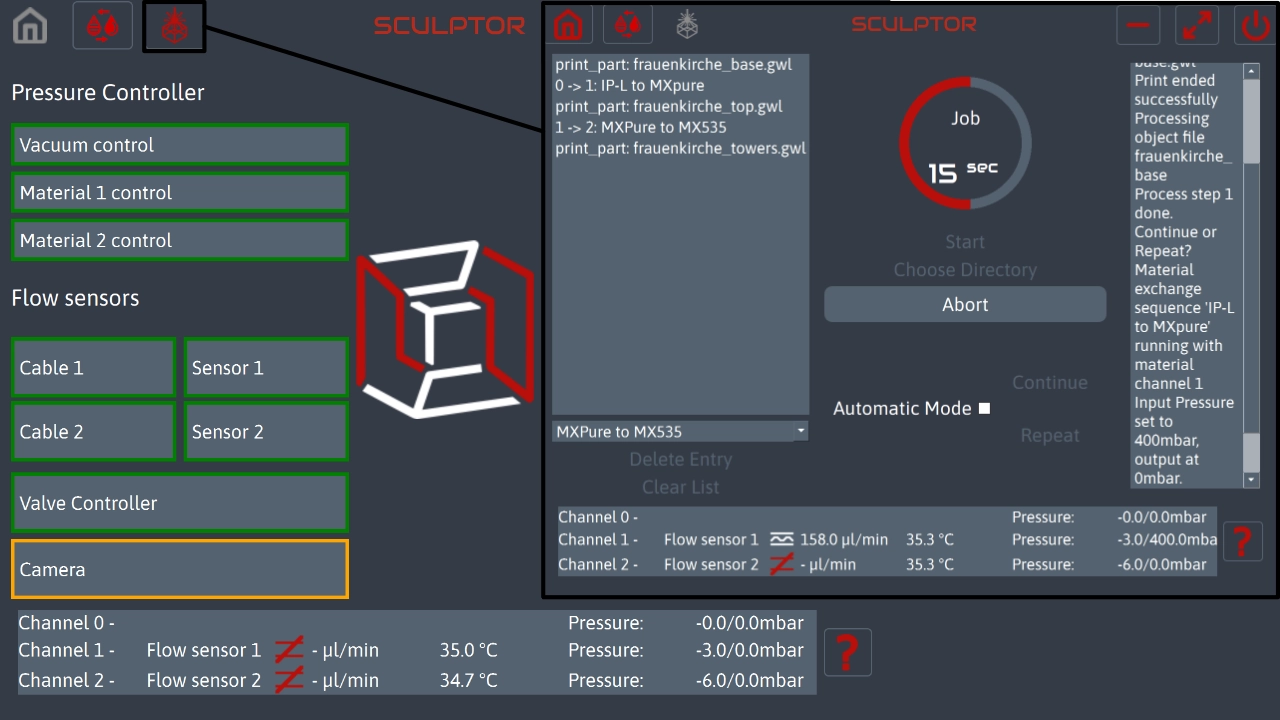

SCULPTOR control software

SCULPTOR controls your multi-material print processes. It communicates with the printer, with sensors and actors, which grants you a convenient object development workflow as well as a fully automated printing of your products. Within this software, we provide standard exchange recipes for tested and certified materials.

Hardware control electronics

The hardware control is the system interface between SCULPTOR, the 2PP printer, and the printhead. It provides precision regulated pressure and vacuum to drive the open-fluidic exchange technology. It is connected to our own laser-safe system feedthrough into the 2PP system and the resin reservoirs. It can remain permanently installed without affecting the 2PP printer.

Support and auxiliary components (separately available)

We provide additional features to ensure a simple to learn, confident and 2PP system safe multi-material printing by the following components, which are also separately available without MergeOne.

- Full print area surveillance with additional camera

- Washing station for system purging

- Objective sealing system to avoid resins spills

- Damping system for piezo protection during handling

Contact us for details or your individual MergeOne quotation:

SELECTED MergeONE CustomerS

MERGECAM - the process monitoring camera

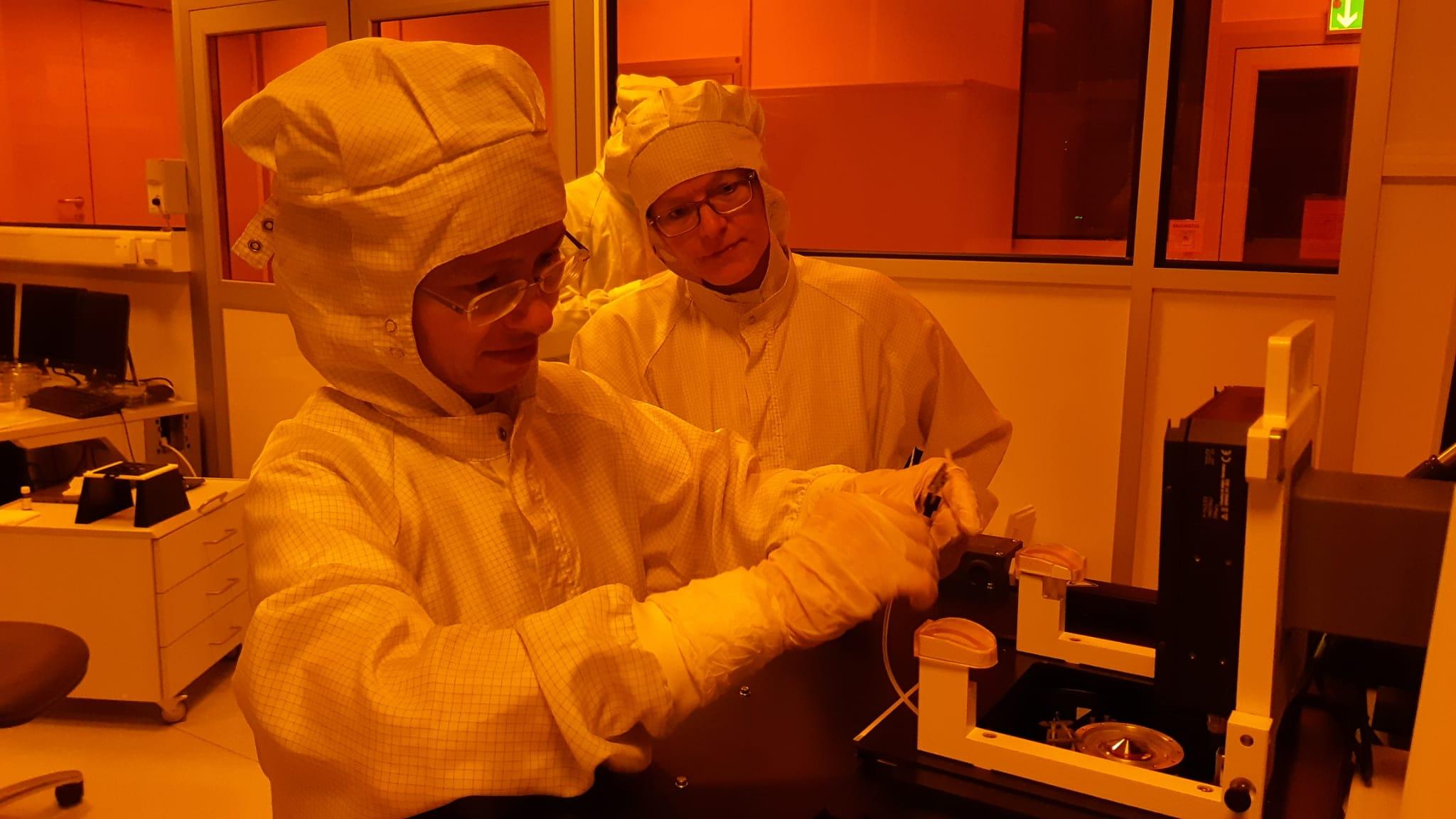

MergeCam provides new level of process monitoring during material exchange, sample approach and stage movement. Advanced vision with a large field of view supports easy user orientation. Even pre-alignment to existing surface topography like metallization pads or fluidic channels is possible now.

It supports multi-user facilities in efficient user training and tool-safe operation as well as advanced users with novel alignment options and workflow improvements.

MergeCam is included in the MergeOne and also availabe as seperate product for Nanoscribe Photonic Professional GT systems while maintaining user-known workflows.

MergeCam features

- Full-field top-view on substrate holder

- Advanced and safe alignment on challenging substrates

- User known transmission illumination

- Upgrade kit for transmission LED

- Assembly instructions + supervised online training

MergeCam specifications

- Adjustable field of view up to 10 cm by 10 cm

- Pre-adjusted fixed focus

- 8.2 MP, 45 fps, color CMOS

- USB 3.0 high-speed communication

- Compatible with third party software

Tell us your needs and get your MergeCam quotation:

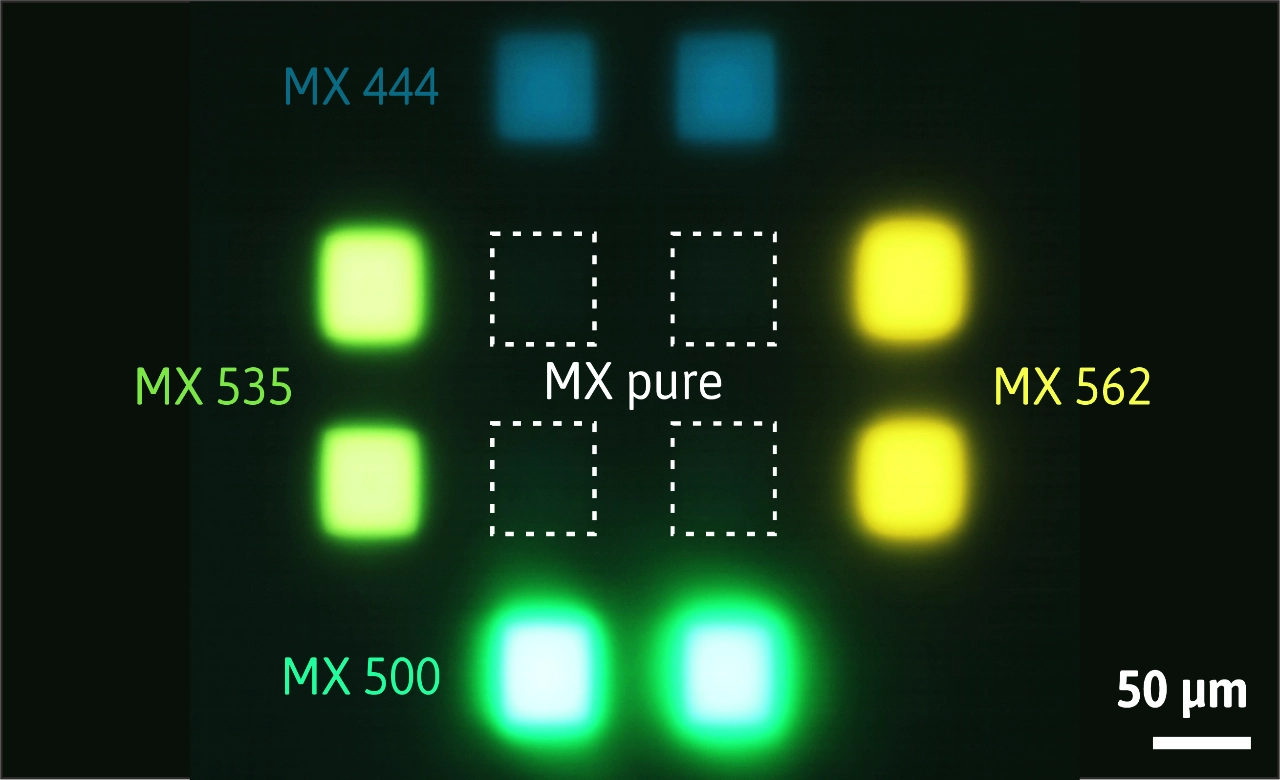

MX materials

MX materials are our functional printing materials designed and optimized for best multi-material printing experience with the MergOne system.

Our fluorescent and optically active, low-viscosity MX materials are unmatched in their ability for fast material exchange.

With them, you can easily functionalize, label and identify your high-resolution 3D structures with sub-micron precission.

Our MX materials are highly compatible with other state-of-the art 2PP 3D printing materials.

Material specifications

- Viscosity: 821 mPas (typical)

- Refractive index: 1.48 (589 nm, 20°C)

- Exchange time down to 30 s (w/o topography)

- Laser power 780 nm 25 mW (PPGT2, LP 50 %)

- Writing speed 60 mm/s (PPGT2, typical)

- Functional element Fluorescence dye, quantum dots

Contact us for more material details:

Services

If you do not possess your own 2PP system or want to determine if the HETEROMERGE® technology can realize your products and multi-material 3D microstructures, we provide various levels of multi-material testing and printing services..

MergeCheck

You have an idea or already a CAD file of your desired multi-material 3D microstructure and want to check whether it can be implemented using our process.

MergeStudy

Your desired multi-material 3D microstructure is feasible and you want to test whether and how it can be implemented with our printing process.

MergeScale

Our printing process is already optimized for your multi-material 3D microstructure and you want to produce it in larger volumes.

Challenge us with your multi-material 3D microstructure: