Micro-Optics and Beyond

Micro-optics

and

beyond

FUNCTIONAL 3D MICRO-PRINTING FOR YOUR PRODUCTS

We define additive fabrication at the micrometer level that exploits the specific properties of different materials as functional 3D micro-printing. Several applications like optics, biotech, fluidics, and mechanics do benefit from that.

The HETEROMERGE® technology fulfills customer needs for heterogeneous composites consisting of different materials. We enable printing of high and low optical refractive index, high and low elastic modulus, fluorescenct and non-fluorescenct, optically active and passive materials, and more. We add functionality to additive fabrication from rapid prototyping up to medium-volume production.

Below are selected applications we are currently working on. Are you interested in other applications joining versatile materials in one print run? Contact us, we will support you!

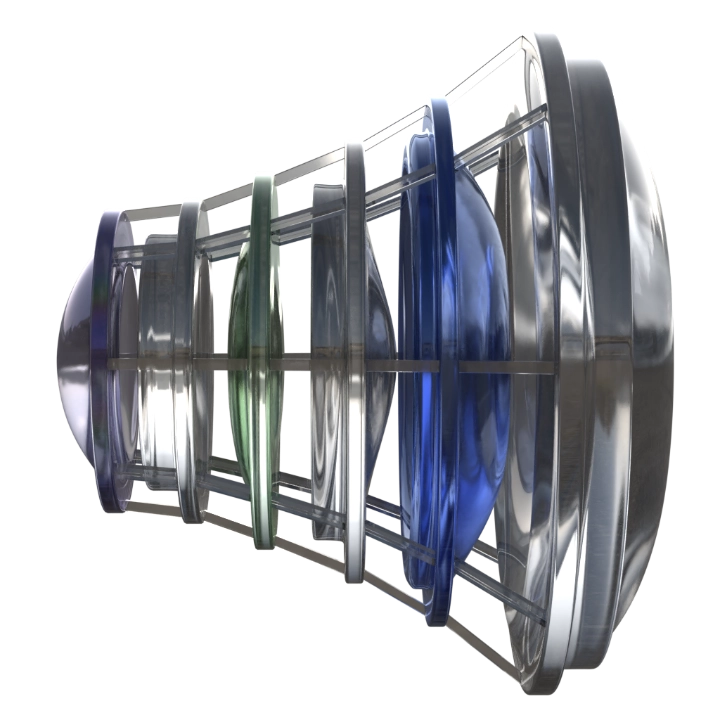

MULTI-MATERIAL LENS SYSTEMS

Multi-material (compound) lens systems consist of individual lenses, each with a different optical dispersion (refractive index). 2PP 3D printed polymer optics offer superior surface finish (<10 nm RMS) and can be fully free-form. This simplifies the design process due to free-form manufacturing, reduces costs thanks to faster and easier assembly, and minimizes weight as well as mechanical impact sensitivity due to the used polymers.

While 2PP 3D laser printing achieves the necessary optical quality, our multi-material technology optimizes the properties of broad-band optical lenses, supports tighter focus, and improves off-axis performance. This enhances image quality, increases precision in beam scanning, boosts optical fluence in the focus, and enhances tolerance in optics positioning.

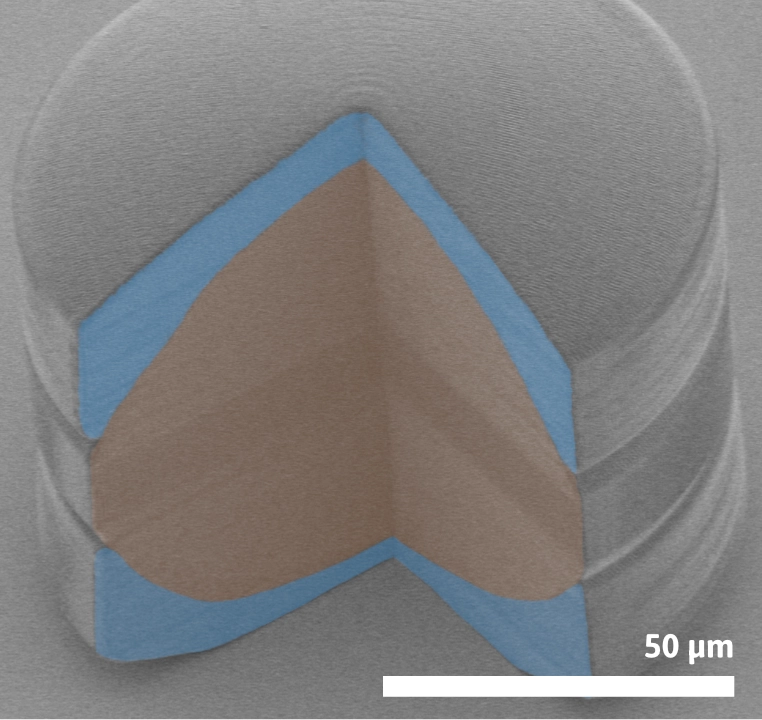

Multi-Material Photonics Packaging

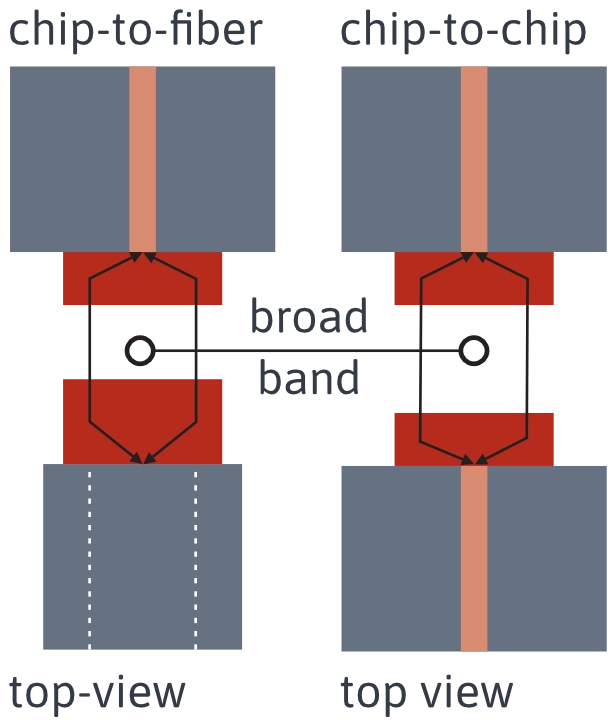

Photonics packaging provides optoelectronic connections between photonic integrated chips (PICs) and chip periphery. It ensures also mechanical and environmental integrity. Today, increasing data traffic, like for large AI model training, requires photonics packaging. Optical interconnects have to come closer to the electric chip level.

While 2PP 3D printing of optical components renders packaging tolerant against the existing variety of PIC and active component technology, helping contract manufacturers to efficiently provide photonic packaging solutions with short lead time, the HETEROMERGE technology solves their challenges in application-specific functional 3D printing, aberration-optimized designing, automated multi-material fabrication, precise alignment, and efficient coupling.

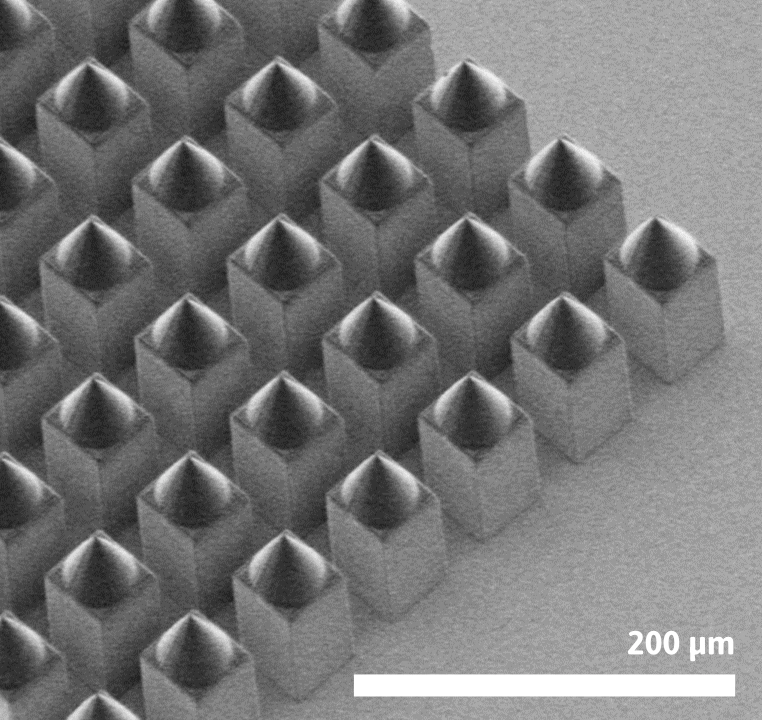

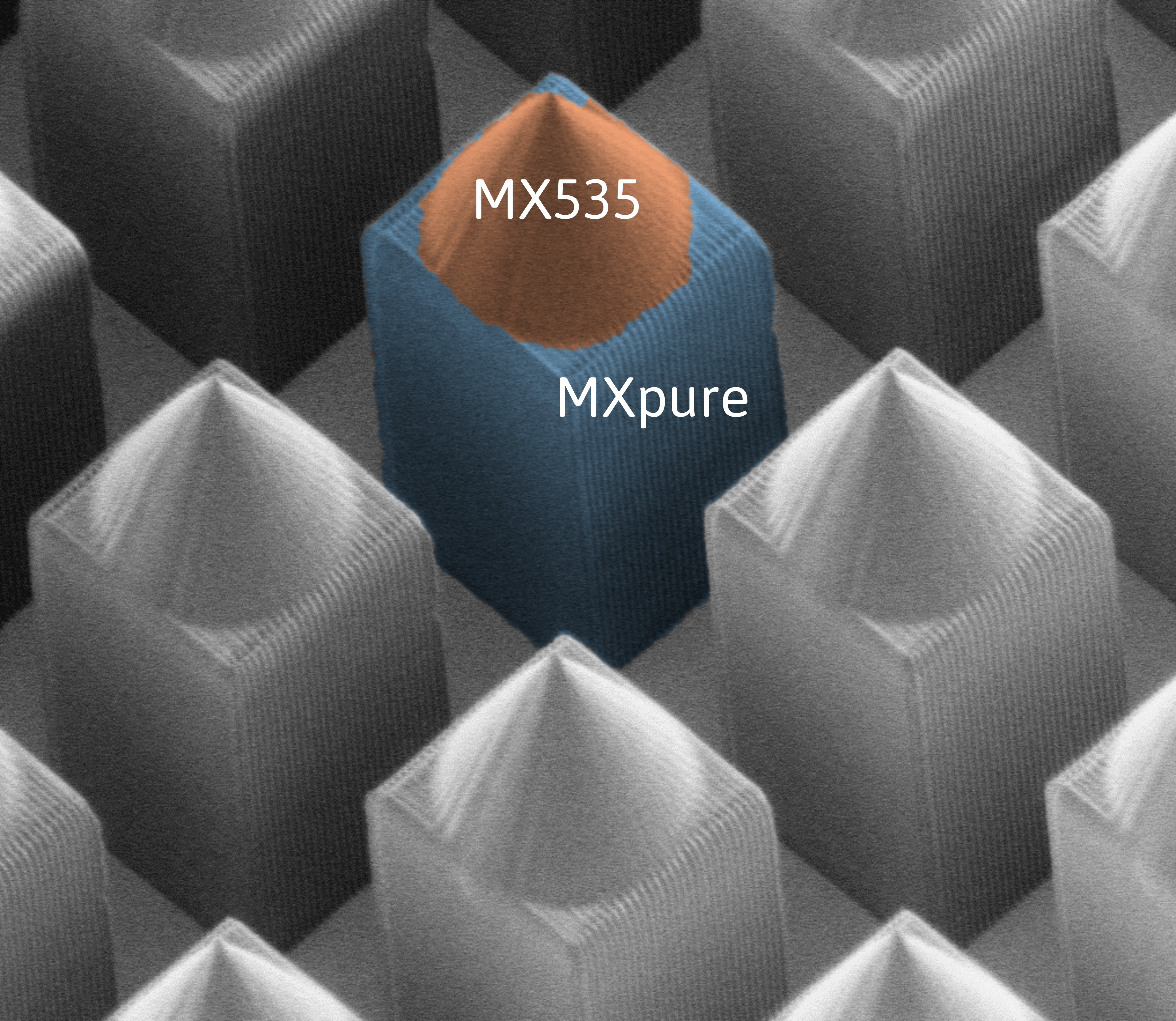

MULTI-MATERIAL MICRO NEEDLES

Advanced microneedles are necessary for reducing patient pain and tissue damage through drug and bioagent delivery. 2PP 3D printing allows for both rapid manufacturing turnarounds and personalized customization at the point of care.

While 2PP 3D laser printing achieves features smaller than 500 nm and extremely smooth surfaces, our multi-material technology allows for combining different materials within a single print run to optimize the mechanics and biocompatibility of microneedles.