Microtechnology advances drug and bioagent delivery

05.06.2023

We enable printing microneedles from two different materials to optimize mechanical stability and the biocompatibility of microneedle arrays.

Microtechnology advances microneedles for drug and bioagent delivery by reducing patient pain as well as tissue damage due to miniaturized fabrication methods. High resolution 3D printing enables rapid turn arounds in fabrication as well as personalized customization in point-of-care environments for smallest feature sizes. One challenge is combining sub 5 um feature resolution with suitable materials that satisfy both biocompatibility and mechanical needs at the same time. Two-photon-absorption (TPA) based 3D laser printing can reach smallest features well below 500 nm and smoothest surfaces. We provide a multi-material system for TPA printers based on an automated, efficient and high-accuracy in-situ material exchange.

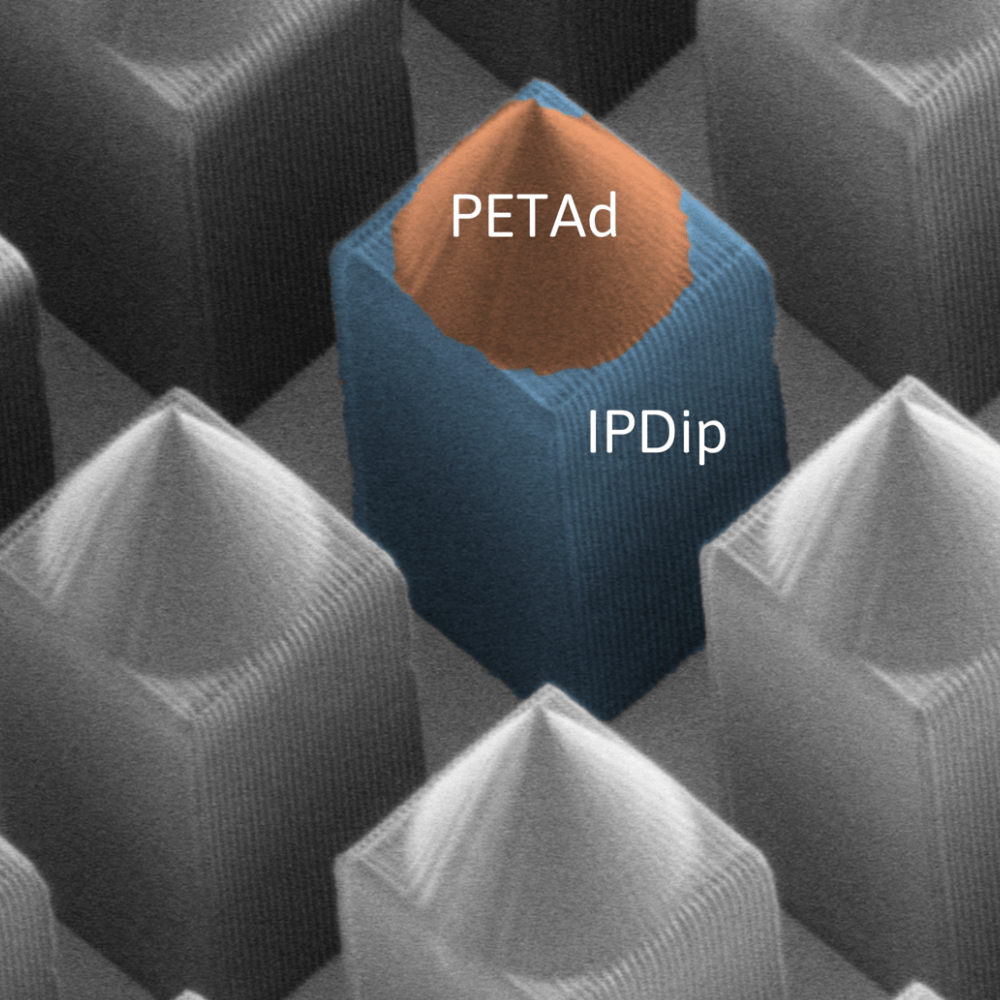

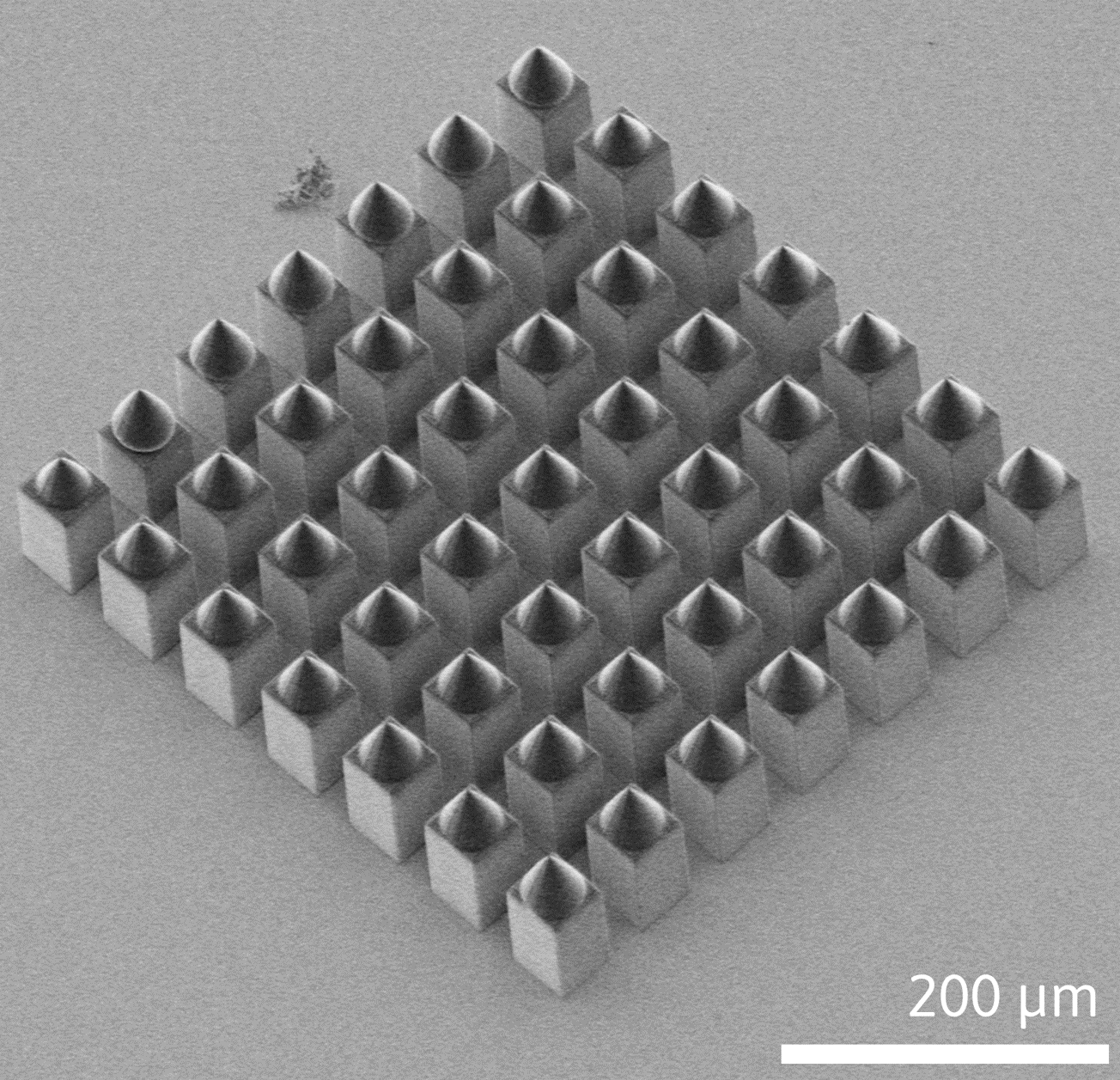

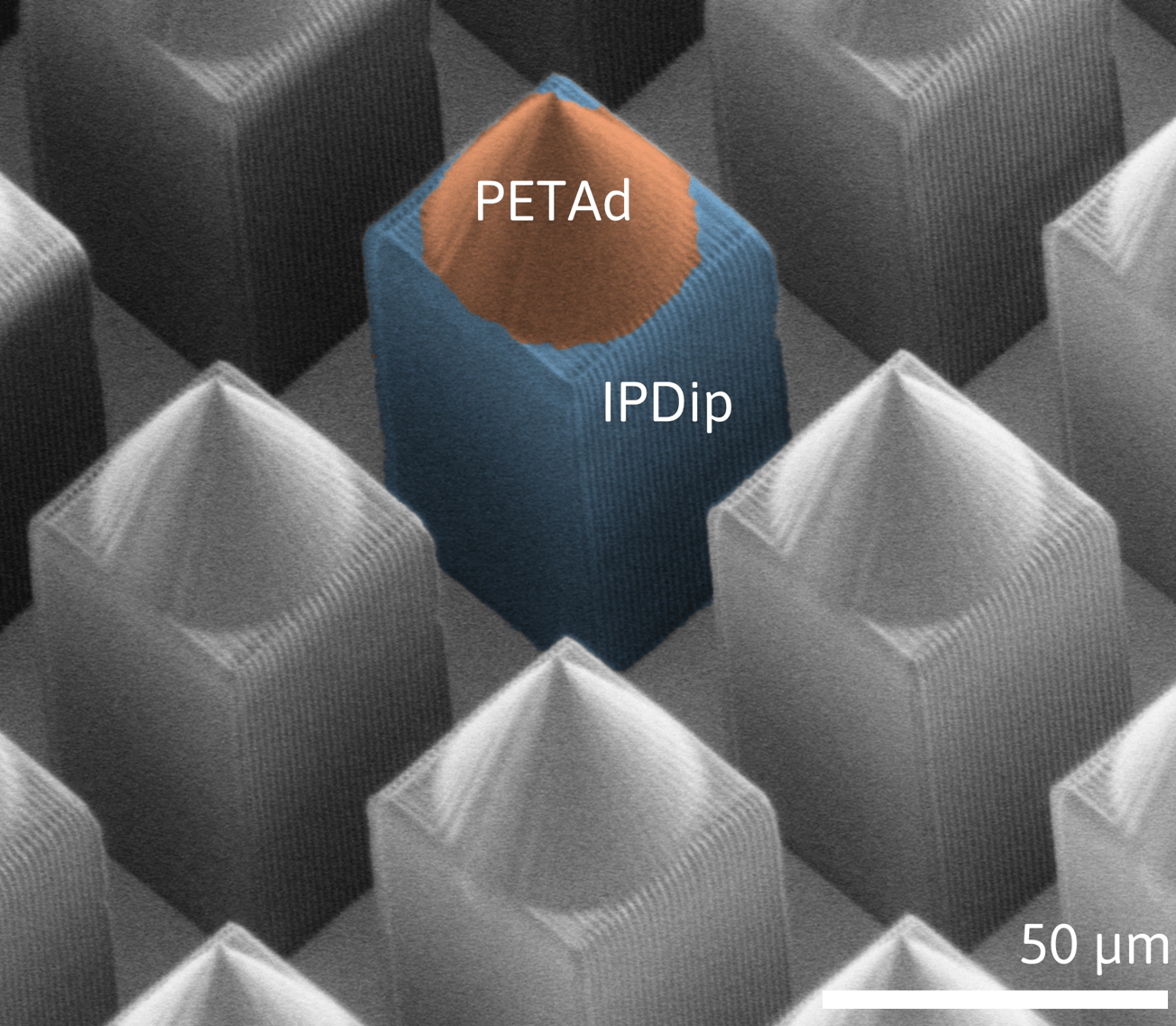

The pictures show an overview, zoom-in and close-up for about 30 micrometer wide and 75 micrometer tall microneedles, where the base is printed from the commercial print material IP-Dip and the top segment is automatically printed onto the base using our customized dye doped material PETAd along with our by our MergeOne print head installed into a Nanoscribe GT2 printer system TU Dresden.